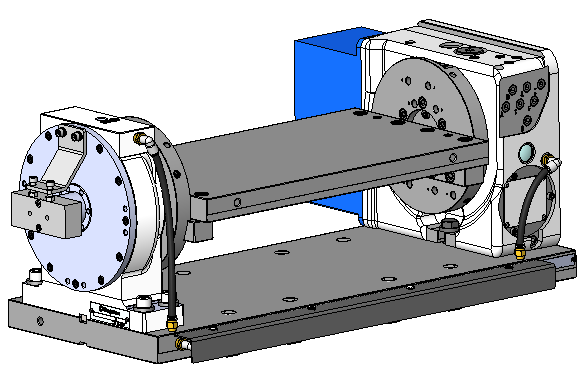

NC ROTARY TABLE

Product Specifications

| Model | CK160 | CKR160 | |||

|---|---|---|---|---|---|

| Right-handed type | ○ | ○ | |||

| Left-handed type | ○ | ○ | |||

| Table Diameter (mm) | ø114 | ø114 | |||

| Centre Hole Diameter (mm) | ø65H7 | ø65H7 | |||

| Through Hole Diameter (mm) | ø65 | - | |||

| Centre Height (mm) | 140 | 140 | |||

| Clamping Method | Pneumatic | Pneumatic | |||

| Clamping Torque (N・m) (at 0.5 MPa) |

340 | 340 | |||

| Motor Axis Reduction Inertia (kg・m2) | 0.00009 | 0.00009 | |||

| Servomotor (for Fanuc spec.) | αiF 2/5000-B | αiF 2/5000-B | |||

| Total Reduction Ratio | 1/72 | 1/72 | |||

| Max. Rotation Speed (min-1) | 41.6 (at motor 3000min-1) |

41.6 (at motor 3000min-1) |

|||

| Allowable Work Inertia (kg・m2) | 0.51 | 0.51 | |||

| Indexing Accuracy (sec) | 20 | 20 | |||

| Repeatability (sec) | 4 | 4 | |||

| Mass of Product (kg) | 40 | 41 | |||

| Allowable Load | Horizontal (kg) | 160 | 160 | ||

| Vertical (kg) | 80 | 80 | |||

| Tail Spindle (as an option) | MSRC140/TSRC140 MSR142A/TSR142A |

MSRC140/TSRC140 MSR142A/TSR142A |

|||

| Rotary Joint (as an option) | - | Note 1) |

|||

| Outline Drawing | Kitagawa Own Controller Spec. | 2D |   |

|

|

| TIF |   |

|

|||

| DXF |   |

|

|||

| DWG |   |

|

|||

| 3D | Parasolid |   |

|

||

| STEP |   |

|

|||

| 4th axis spec. (Fanuc spec.) | 3D | Parasolid |   |

|

|

| STEP |   |

|

|||

| Option Outline Drawing |

Tail Spindle | ||||

| Model | CK200 | CKR200 | |||

|---|---|---|---|---|---|

| Right-handed type | ○ | ○ | |||

| Left-handed type | ○ | ○ | |||

| Table Diameter (mm) | ø130 | ø130 | |||

| Centre Hole Diameter (mm) | ø65H7 | ø65H7 | |||

| Through Hole Diameter (mm) | ø65 | - | |||

| Centre Height (mm) | 150 | 150 | |||

| Clamping Method | Pneumatic | Pneumatic | |||

| Clamping Torque (N・m) (at 0.5 MPa) |

400 | 400 | |||

| Motor Axis Reduced Inertia (kg・m2) | 0.00017 | 0.00017 | |||

| Servomotor (for Fanuc spec.) | αiF 2/5000-B | αiF 2/5000-B | |||

| Total Reduction Ratio | 1/120 | 1/120 | |||

| Max. Rotation Speed (min-1) | 25 (at motor 3000min-1) |

25 (at motor 3000min-1) |

|||

| Allowable Work Inertia (kg・m2) | 1.00 | 1.00 | |||

| Indexing Accuracy (sec) | 20 | 20 | |||

| Repeatability (sec) | 4 | 4 | |||

| Mass of Product (kg) | 47 | 49 | |||

| Allowable Load | Horizontal (kg) | 160 | 160 | ||

| Vertical (kg) | 80 | 80 | |||

| Tail Spindle (as an option) | MSRC150/TSRC150 | MSRC150/TSRC150 | |||

| Rotary Joint (as an option) | - | Note 1) |

|||

| Outline Drawing | Kitagawa Own Controller Spec. | 2D |  |

|

|

| TIF |  |

|

|||

| DXF |  |

|

|||

| DWG |  |

|

|||

| 3D | Parasolid |   |

|

||

| STEP |   |

|

|||

| 4th axis (Fanuc spec.) | 3D | Parasolid |   |

|

|

| STEP |   |

|

|||

| Option Outline Drawing |

Tail Spindle | ||||

Note 1) All ports are available for both pneumatic and hydraulic, not available for coolant.

Note 2) Please consult Kitagawa distributor for Tail stocks.

Precautions for using the Trunnion jig

To prevent potential issues caused by chips or debris when using the cradle jig, please read the following instructions carefully.